Overview of Graphite Ore Flotation

Release time:

2016-11-25 00:00

Graphite mainly refers to natural graphite, which is a non-metallic mineral formed under specific high-temperature reduction conditions of carbon element, and is most commonly found in marble, schist and gneiss.

Graphite is widely used in steel, chemical industry, machinery, electronics, aerospace, national defense and military industry and other fields due to its excellent high temperature resistance, thermal shock resistance, conductivity, lubrication, chemical stability, plasticity and many other characteristics. It is an indispensable strategic resource in the development of military industry and modern industry. Due to the wide application of graphite, some experts predict that the 20th century will be“ The Age of Silicon”, The 21st century is“ The Graphite Age.

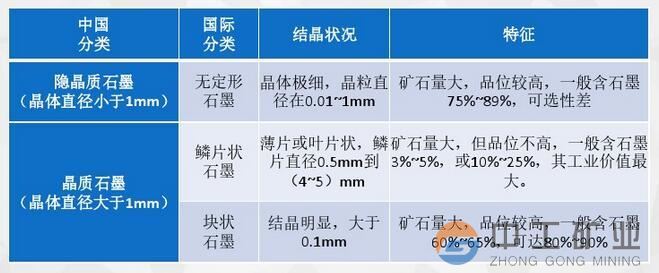

According to the crystalline morphology of graphite, natural graphite can be divided into crystalline graphite and aphanitic graphite. The crystal diameter of graphite is larger than 1 mu; m. Graphite whose crystal shape can be observed by naked eye or ordinary microscope is called crystalline graphite; The diameter of graphite crystal is less than 1 mu; m. Dense graphite aggregates that are difficult to identify crystal forms under a microscope are called aphanitic graphite or amorphous graphite. Because most aphanitic graphite is black earthy, they are also called earthy graphite and microcrystalline graphite.

Distribution of graphite resources in China

China is rich in graphite resources. China's graphite resources account for more than 70% of the world's resources. It is one of the few countries in the world with crystalline graphite and aphanitic graphite.

According to the statistics of the Ministry of Land and Resources, the reserves of crystalline graphite in China are 30.85 million tons, the basic reserves are 52.8 million tons, and the resource amount is 170 million tons. The graphite mineral reserves are large; Most of the deposits are dominated by medium scale (+200 mesh), while a few deposits are dominated by fine scale (0.074 ~ 0.01 mm). The graphite deposit conditions are good; Crystalline graphite is easy to separate, with high mineral recovery and strong mining and dressing ability. It is the largest supplier of international crystalline graphite market. Most of China's crystalline graphite deposits are large and medium-sized, which are mainly concentrated in several provinces. Heilongjiang Province has 22 million tons of developable graphite reserves, Shandong Province has 12 million tons of developable graphite reserves, and Inner Mongolia has 4 million tons of developable graphite reserves. Three major production bases have been formed, including the Baiyunshan graphite deposit in Luobei County, Heilongjiang Province, the Nansha graphite deposit in Laixi County, Shandong Province, and the Xinghe graphite mining area in Inner Mongolia.

The reserves of aphanitic graphite are 13.58 million tons, and the basic reserves are 23.71 million tons. The cryptocrystalline graphite is mainly small and medium-sized, mainly distributed in Hunan, Guangdong, Jilin and other provinces and regions. The mining areas with large reserves include the Lutang mining area in Chenzhou, Hunan Province and the Panshi mining area in Jilin Province. The accumulated proven graphite resource reserves in the Lutang mining area are 31.6482 million tons, and the accumulated mining reserves are 21.7524 million tons, accounting for 75% of the national cryptocrystalline graphite reserves.

Flotation of crystalline graphite

The flake graphite has good natural floatability and low density, so the coarse particle flake graphite is easy to float. Kerosene and diesel oil can be used as flotation collectors, and terpineol oil is commonly used as foaming agent. The scale graphite ore mostly contains gangue minerals such as calcite and pyrite, which need to add inhibitors such as lime and sodium silicate; For carbonaceous shale, starch and lignosulfonic acid can be added as inhibitors. Rare metals such as vanadium contained in graphite ore should be recovered to improve economic benefits.

Stage flotation: in order to protect the scales from being damaged, stage grinding flotation process is adopted during flotation; After rough grinding, rough separation is carried out to obtain coarse concentrate and waste tailings, and then the coarse concentrate is reground and reselected for many times.

Multiple cleaning: the grade of the coarse concentrate obtained from the roughing is low, while the fixed carbon content of graphite products is generally required to be more than 85%, which requires multiple cleaning.

Flotation of aphanitic graphite

The natural floatability of aphanitic graphite is poor, and the grade of raw ore is high, up to 70% - 80%. However, graphite particles are closely embedded with clay, which makes separation difficult, so it is difficult to separate. In industrial production, the grade of aphanitic graphite concentrate can be increased to more than 80% through grinding and flotation, but it is difficult to reach 90%, even if the number of regrinding times is increased, the grade of concentrate will not be improved much. The flotation of aphanitic graphite can only play a role of roughly enrichment, so the concentrate and tailings can be sold as products of different grades. Flotation characteristics of aphanitic graphite: large amount of flotation collector, slow flotation speed, low concentrate recovery and high tailings grade.

Some mineral processing researchers conducted comparative studies on flotation equipment and found that better flotation effect can be obtained by using flotation column as the flotation equipment of aphanitic graphite.

The ZGF-I flotation column, developed and manufactured by Hunan Zhonggong Mining Engineering Technology Co., Ltd., is a micro bubble countercurrent contact flotation column, which has the advantages of high beneficiation efficiency, low operating cost, energy consumption reduction, high automation, simple operation, convenient maintenance, less floor space and infrastructure investment.

ZGF-I flotation column is as shown in the figure. A microbubble generator is used to inject gas into the column, and a large number of microbubbles are produced by spraying; The ore particles and gas are in steady contact with each other in countercurrent in the column, and hydrophobic ore particles are captured to form foam concentrate; The liquid level and the thickness of foam layer are adjusted by the liquid level control system.

Relevant mineral processing knowledge

Molybdenum resource reserve distribution and output

The average content of molybdenum in the crust is about 0.00011%. There are about 20 kinds of molybdenum ores found, among which molybdenite is the most valuable one, followed by tungsten phase calcium ore, iron platinum ore, color molybdenum lead ore, platinum copper ore, etc. According to the data released by the US Geological Survey in 2015, the global molybdenum resource reserves are about 11 million tons, and the proven reserves are about 19.4 million tons

Overview of Graphite Ore Flotation

Graphite mainly refers to natural graphite, which is a non-metallic mineral formed under specific high-temperature reduction conditions of carbon element, and is most commonly found in marble, schist and gneiss

Deep sea mineral - manganese nodule

The ocean floor is rich in mineral resources, and manganese nodules are one of them. It contains more than 30 kinds of metal elements, among which manganese, copper, cobalt and nickel are the most valuable for commercial development.