The serious shortage of copper resources in China is of great significance in the resource utilization of copper smelting slag

Release time:

2016-12-23 00:00

Distribution characteristics of copper resources

The world is rich in copper resources, with a total of 3.7 billion tons, including more than 3 billion tons of copper on land and 700 million tons of copper nodules in the sea. The world's copper resources are mainly distributed in North America, Latin America and Central Africa. According to statistics, by the end of 2012, the world's proven copper reserves and basic reserves were 680 million tons and 1065 million tons, respectively. These copper resources cover six continents, distributed in more than 150 countries, and some countries have a mining life of more than 100 years. Among them, Chile has 190 million tons of copper reserves, ranking first in the world, followed by Australia, Peru, the United States and Mexico, and China has 30 million tons of copper reserves, ranking sixth. Table 1-1 shows the output and reserves of major copper ores in the world.

China is one of the countries with more copper mines in the world. As of the end of 2010, the verified resource reserves of copper mines in China were 80.407 million tons, a net increase of 144000 tons or 0.2% over 2009. Copper ores in China are mainly distributed in Tibet, Jiangxi, Yunnan, Anhui, Hubei and other places. From the perspective of deposit scale, copper grade and mining conditions, China's copper resources have the following characteristics:

(1) The deposit is small in scale, mostly small and medium-sized. The proportion of large copper deposits in China is less than 3%, and that of small copper deposits is as high as 88.4%. (2) There are many associated ores with low grade. Among the proven copper deposits in China, the copper grade is lower than 0.7%, and the resource reserves account for 56%. The average grade of porphyry copper deposits generally only reaches about 0.5%, which is far lower than the copper ore grade of Chile, Zambia and other countries. (3) Most of the newly discovered copper deposits with large scale and high grade are located in remote areas, where the construction conditions are poor and it is difficult to develop and utilize them.

Supply and demand status of copper resources

Since the 1990s, China has been in the stage of rapid industrialization development, with rapid development of automobile, construction, electric power and other industries. China's consumption of copper has maintained a rapid growth trend, with copper consumption growing faster than copper output. Copper products are in short supply. China has become the world's largest importer of copper concentrates. Copper and its alloy materials are widely used in electric, automobile, construction industry, national defense industry and other fields, and are second only to aluminum in the consumption of nonferrous metal materials in China.

Figure 2 shows the production and consumption of refined copper in China from 2003 to 2010. China's copper industry has made great progress. Although China has a copper smelting capacity of 3 million t/a, the copper concentrate produced by itself is less than 1 million t/a, the self-sufficiency rate of China's copper concentrate is less than 30%, and the dependence on foreign countries is high. China has developed into the world's largest copper consumer, copper processing and manufacturing base, and copper basic product exporter.

Current situation of copper smelting slag beneficiation and recovery

At present, domestic copper smelting raw materials are very scarce. Most of them rely on imported copper concentrates to maintain copper smelting production, while the market price of imported copper concentrates is gradually rising, which has aroused great attention of domestic copper smelting enterprises, who have changed from discarding copper smelting slag to recovering it through beneficiation and flotation methods.

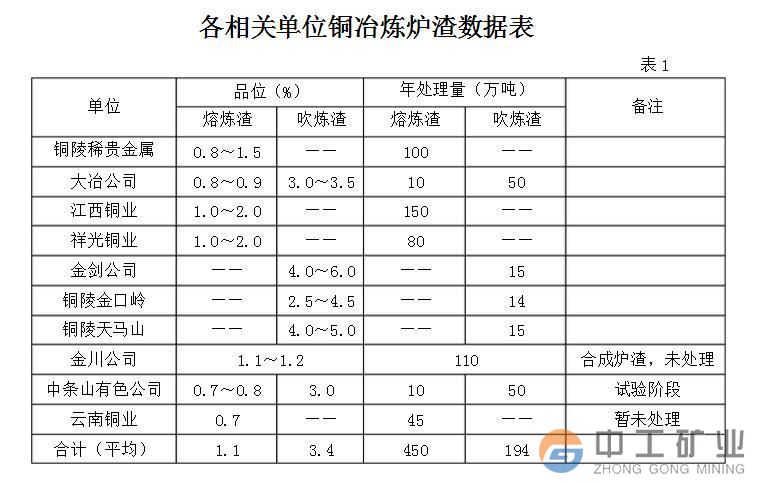

At the same time, the copper smelting slag in China is about 4-5 million tons per year, and has accumulated more than 50 million tons so far. These slag contains a considerable amount of precious metals and rare metals. Long term stacking of these slag not only occupies a lot of land, but also seriously pollutes the environment, and is a serious waste of resources. Therefore, the development and utilization of secondary resources can not only maximize the reuse of resources, bring considerable economic benefits to enterprises, but also become an important way to achieve sustainable development.

Basic properties of copper smelting slag

At present, the domestic copper smelting mainly adopts the secondary copper smelting process of smelting and converting. The smelting slag produced by the previous first process is basically discarded as waste due to low copper content, and some of it is also sold as additives in the construction industry. Due to the relatively high copper content of the converting slag produced by the second process, some manufacturers return to the previous process for use, and some adopt beneficiation enrichment for reuse.

The copper recovered from smelting slag or converting slag is basically the same in nature as the copper concentrate selected from copper minerals mined underground and on the surface, except for its low sulfur grade and fine particle size. Each smelter uses this product with copper concentrate.

The mineral composition of copper smelting slag is relatively complex, generally containing a variety of oxides, sulfides and sulfates. Copper smelting slag is generally black or black green in appearance, dense and hard, with a specific gravity of about 4. The copper smelting slag contains the most iron and silicon. The iron bearing minerals are mainly ferruginous olivine, magnetite and a small amount of pyrrhotite. The majority of silicon slags to produce iron silicates, and a small amount of silicon appears as wollastonite and opaque glass; The second is copper sulfide, metal copper and a small amount of copper oxide; Copper smelting slag also contains valuable components such as gold, silver, nickel and cobalt.

Flotation characteristics of copper smelting slag

High concentration grinding: due to the characteristics of the mineral composition and structure of copper smelting slag, the copper smelting slag has high density and hardness, so high concentration grinding is used for grinding treatment. With the increase of grinding concentration, the distribution rate of coarse and fine particles decreases, and the distribution rate of intermediate particles increases, which is conducive to the improvement of beneficiation indexes.

High concentration flotation: due to the high density of copper smelting slag, less slime content and fast settling speed, higher flotation concentration should be adopted during flotation. In production practice, the flotation concentration of copper smelting slag is about 15% higher than that of ordinary ores. For example, in the flotation production of copper smelting slag in Guixi Smelter, the concentration of roughing, concentration and scavenging operations are 44%, 35% and 49% respectively.

Stage grinding flotation process flow: most copper smelting slag concentrators adopt stage grinding flotation production process, and set up intermediate flotation operation in the grinding circuit to directly flotation to obtain high-grade copper concentrate.

At present, the flotation recovery of copper from oxygen enriched smelting slag and converter slag has been widely used in copper smelting industry. Smelting slag is treated by beneficiation method, with high recovery rate, low cost and good enrichment effect. It is one of the most economical and effective methods to recover copper from smelting slag. The copper flotation recovery rate is generally above 90%, the copper content of copper concentrate obtained is more than 20%, and the copper content of tailings is 0.3% - 0.5%.