Industrial flotation column

The flotation column produced by our company is inflatable flotation column, which is mainly used for recovery and separation of non-ferrous, black, non-metallic minerals and secondary resources.

Classification:

Industrial flotation column

Product Introduction

Introduction

The flotation column produced by our company is inflatable flotation column, which is mainly used for recovery and separation of non-ferrous, black, non-metallic minerals and secondary resources.

Features

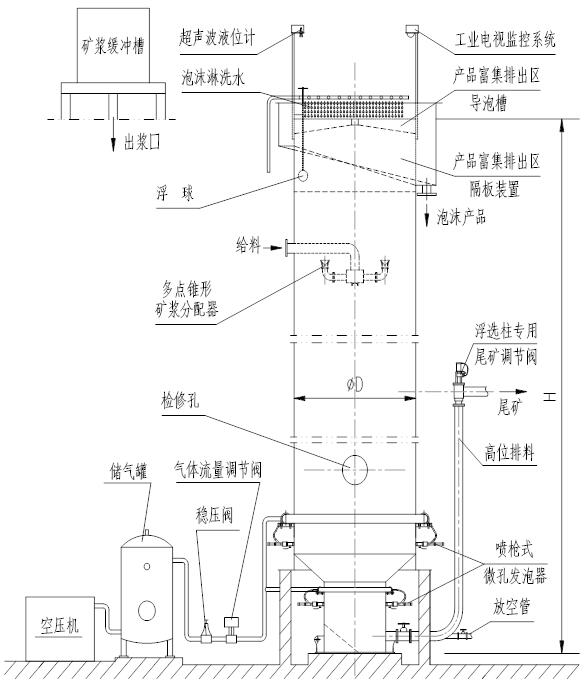

The flotation column is a high column countercurrent non filling flotation column, including main components such as ore feeding device, tailing device, column, inflation device, foam rinsing water device and industrial automatic control system. Its working characteristics are as follows:

1. It has a larger mineralization area than conventional mechanical stirring flotation machine. The mineralization zone of the former is only in the high shear zone around the rotor, while the whole capture zone of the counter flow flotation column from the feed inlet to the bubble inlet is a mineralization zone, so the volume utilization rate is high and the processing capacity per unit volume is large.

2. The collision and adhesion probability between mineral particles and bubbles is high. The movement direction of mineral particles and bubbles in the mechanically agitated flotation machine is basically the same when they are thrown out at high speed, depending on the speed difference between the two in turbulent flow. The movement of particles and bubbles in the countercurrent flotation column is generally opposite. Although the absolute speed of movement is small, the relative speed is not small. Due to low turbulence and energy consumption, the separation probability of particles and bubbles is low.

3. The bubble generated by the flotation column has a high degree of dispersion and many micro bubbles, so the same aeration volume can produce a larger gas-liquid interface, more opportunities to collide with mineral particles, and can generate gas solid flocs with multiple bubbles adhering to a particle, reducing the probability of bubbles and particles falling off. In addition, a large number of micro bubbles rise slowly and are basically in laminar flow, which creates favorable conditions for collision with particles, and also improves the flotation rate and recovery.

4. The content of impurities is reduced. The foam of the mechanically stirred flotation machine often carries more impurities, while the countercurrent flotation column has low turbulence, and the top has a thick foam layer and foam rinsing water. Through the multiple annexation and rinsing of foam in the thick foam layer, various gangue impurities carried between the foam are forced out, which is conducive to the improvement of the final concentrate grade.

5. Technical principle: Pulp is fed from the ore feed port into the flotation column barrel. Under the action of foam generated by the spray gun at the bottom of the flotation column, useful minerals are taken to the top of the flotation column by the foam, and gangue is discharged from the bottom of the flotation column. According to the difference in the hydrophobicity of various mineral surfaces (or treated surfaces) in the ore, the separation of various minerals can be achieved under the action of solid, water and gas three-phase fluids, and the working liquid level height and inflation volume are operated and managed by the automatic control system.

6. The main parts of the equipment will not affect the environmental energy, and some electronic components of its control system need to be recycled.

Schematic Diagram

Technical parameters

|

Serial No |

Specification and model ΦD×H |

Area of foam area m2 |

Feeding concentration % |

Handling capacity m3/h |

Inflation volume m3/h |

|

1 |

Φ400×(8000~14000) |

0.126 |

10-40 |

2-10 |

8-12 |

|

2 |

Φ600×(8000~14000) |

0.283 |

10-40 |

3-11 |

17-25 |

|

3 |

Φ700×(8000~14000) |

0.385 |

10-40 |

4-13 |

23-35 |

|

5 |

Φ800×(8000~14000) |

0.503 |

10-40 |

5-18 |

30-45 |

|

6 |

Φ900×(8000~14000) |

0.635 |

10-40 |

7-25 |

38-57 |

|

7 |

Φ1000×(8000~14000) |

0.785 |

10-40 |

8-28 |

47-71 |

|

11 |

Φ1200×(8000~14000) |

1.131 |

10-40 |

12-41 |

68-102 |

|

12 |

Φ1500×(8000~14000) |

1.767 |

10-40 |

19-64 |

106-159 |

|

13 |

Φ1800×(8000~14000) |

2.543 |

10-40 |

27-152 |

153-229 |

|

14 |

Φ2000×(8000~14000) |

3.142 |

10-40 |

34-203 |

189-283 |

|

15 |

Φ2200×(8000~14000) |

3.801 |

10-40 |

41-237 |

228-342 |

|

16 |

Φ2500×(8000~14000) |

4.524 |

10-40 |

49-263 |

271-407 |

|

17 |

Φ3000×(8000~14000) |

7.065 |

10-40 |

75-435 |

417-588 |

|

18 |

Φ3200×(8000~14000) |

8.038 |

10-40 |

82-456 |

455-640 |

|

19 |

Φ3600×(8000~14000) |

10.174 |

10-40 |

105-535 |

583-876 |

|

20 |

Φ3800×(8000~14000) |

11.335 |

10-40 |

122-608 |

680-1021 |

|

21 |

Φ4000×(8000~14000) |

12.560 |

10-40 |

140-756 |

778-1176 |

|

22 |

Φ4500×(8000~14000) |

15.896 |

10-40 |

176-862 |

978-1405 |

|

23 |

Φ5000×(8000~14000) |

19.625 |

10-40 |

225-960 |

1285-1746 |

|

24 |

Φ5200×(8000~14000) |

21.226 |

10-40 |

243-1038 |

1380-1875 |

|

25 |

Φ5500×(8000~14000) |

23.746 |

10-40 |

272-1161 |

1523Y-2069 |

Related Products

Related Products

Provide you with flotation column solutions and prepare for your choice.