Announcement on the Minimum Indicator Requirements for the Rational Development and Utilization of Mineral Resources

Release time:

2016-12-29 00:00

Reasonable development and utilization of lithium, strontium, barite, limestone, magnesite, boron and other mineral resources; Three rate” Minimum index requirements (trial)

Rational development and utilization of mineral resources“ Three rate” Indicators refer to three indicators ①, i.e. mining recovery rate, beneficiation recovery rate and comprehensive utilization rate, and are the main indicators for evaluating the effectiveness of mining enterprises in the development and utilization of mineral resources. Through research, it is determined that lithium, strontium, barite, limestone, magnesite, boron and other mineral resources should be rationally developed and utilized; Three rate” The minimum index requirements are as follows:

1、 Lithium ore (solid)

(1) Recovery rate.

1. Open pit mining.

The recovery rate of large and medium-sized open-pit mines shall not be less than 92%; The recovery rate of small open-pit mines shall not be less than 90%.

2. Underground mining.

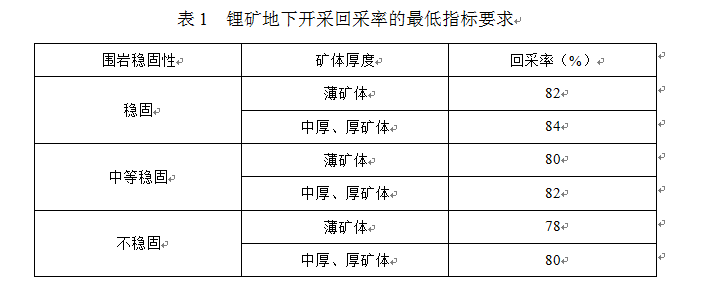

According to the stability of the surrounding rock and the thickness of the ore body, the minimum recovery rate of underground lithium mining is 78~84% (see Table 1 for details).

.

.

(2) Beneficiation recovery rate.

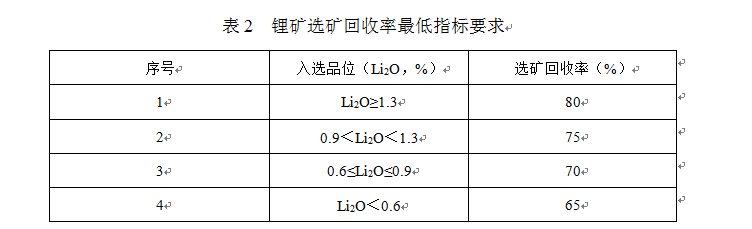

On the basis of ensuring the production of qualified lithium concentrate products, the lithium ore dressing recovery rate shall meet the following index requirements respectively according to the ore structure type, ore dressing grade and other influencing factors (see Table 2 for details).

.

.

(3) Comprehensive utilization rate.

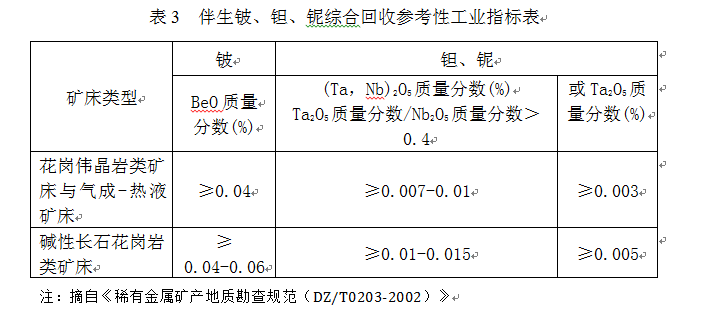

Beryllium, tantalum and niobium are often associated with lithium ores. When the associated useful component minerals reach the content listed in Table 3, the useful component should be comprehensively utilized. Among them, when two rare metals are comprehensively recovered, the comprehensive utilization rate of co associated minerals should be more than 40%, and when more than three rare metals are comprehensively recovered, the comprehensive utilization rate of co associated minerals should be more than 30%. When the lithium ore is spodumene granite pegmatite ore type, the comprehensive recovery rate of tantalum and niobium associated minerals is not less than 15%.

.

.

2、 Strontium ore

(1) Recovery rate.

1. Open pit mining.

The recovery rate of strontium ore open-pit mining shall not be less than 90%; The recovery rate of mines with large change in ore body shape, thin ore body and poor stability of ore rock shall not be less than 85%.

2. Underground mining.

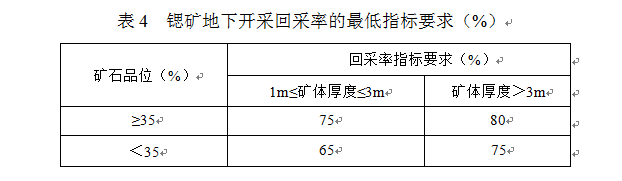

According to the difference of ore grade and ore body thickness, the minimum recovery rate of strontium ore in underground mining is 65% - 80% (see Table 4 for details).

.

.

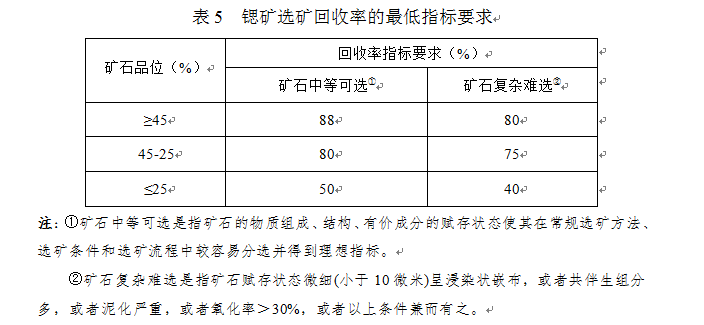

(2) Beneficiation recovery rate.

According to the influence factors such as ore dressing grade and dressing difficulty, it is suggested that the minimum indicators should be 40% - 88% respectively (see Table 5 for details).

.

.

(3) Comprehensive utilization rate.

The strontium mineral is mainly celestite, which is often associated with barite, gypsum and pyrite. When the strontium ore is moderately selectable, the comprehensive utilization rate of its associated minerals is not less than 50%; When strontium ore is complex and difficult to separate, the comprehensive utilization rate of its associated minerals is not less than 40%.

3、 Barite ore

(1) Recovery rate.

1. Open pit mining.

The recovery rate of open pit mining shall not be less than 90%.

2. Underground mining.

The recovery rate of underground mining shall not be less than 85%.

(2) Beneficiation recovery rate.

Not less than 90% of the ore is easy to separate, and not less than 80% of the ore is difficult to separate.

The washability of barite ore mainly depends on the structure of the ore, the types and characteristics of associated minerals. Generally, the ore with simple structure and single associated minerals is called easy dressing ore; The ore with complex structure and associated with quartz, calcite, fluorite and other mineral components is called refractory ore.

(3) Comprehensive utilization rate.

If the co associated mineral is fluorite and the content reaches more than 20%, it shall be comprehensively recycled, and the comprehensive utilization rate of the co associated mineral shall not be less than 75%.

4、 Limestone ore

(1) Recovery rate.

The recovery rate of open pit mining shall not be less than 90%.

(2) Comprehensive utilization rate.

When mining enterprises develop and utilize limestone minerals, they are encouraged to make comprehensive use of the waste rocks from mining and use them as building materials or for backfilling and reclamation of mined out areas. The comprehensive utilization rate shall not be less than 60%.

5、 Magnesite

(1) Recovery rate.

1. Open pit mining.

The recovery rate of open pit mining shall not be less than 90%.

2. Underground mining.

The recovery rate of underground mining shall not be less than 80%.

(2) Beneficiation recovery rate.

When the grade of magnesite is lower than Grade III (MgO≥ 43, CaO≤ 1.5, SiO2≤ 3.5), mineral processing must be carried out for recovery, with the recovery rate not less than 58%.

(3) Comprehensive utilization rate.

When mining enterprises develop and utilize magnesite minerals, they are encouraged to comprehensively utilize low-grade ores, use mining waste rocks and mineral processing tailings, and make building materials or backfill the mine goaf.

6、 Boron ore (solid)

(1) Recovery rate.

1. Open pit mining.

The recovery rate of open pit mining shall not be less than 93%.

2. Underground mining.

The recovery rate of underground mining shall not be less than 80%.

(2) Beneficiation recovery rate.

Only low-grade ludwigite (5%≤ B2O3≤ 11%) ① is beneficiated, and its beneficiation recovery (total boron) is not less than 65%.

(3) Comprehensive utilization rate.

Among boron ores, only low-grade ludwigite ore can comprehensively utilize its co associated iron and uranium minerals, and the comprehensive utilization rate of its co associated minerals is not less than 55%.

Note: ① The standard for low-grade ludwigite comes from the Code for Geological Exploration of Barite, witherite, fluorite and boron ore (DZ/T0211-2002, the Industrial Standard for Geology and Mineral Resources of the People's Republic of China)